China Manufacturer Leaf Chain Long Pitch Flat Top Table Car Parking Drag Sharp Al Bl EL for Mine Machinery Grain Durable Machine Paver Supplyer Forging Stainless Steel Leaf Chains with Great Quality

Our leaf chains, also known as hoisting chains, are made to the highest standards, including ISO, DIN, and ANSI. Available in various models, including LH, LL, and AL series, our leaf chains are made with high-quality carbon steel 40Mn and all parts are heat-treated (quenching and tempering) with excellent grease lubrication. Our chains have a tensile strength 15-20% higher than standard chains and are centerless ground. We also offer a Certificate of Quality, including ISO 9001 and SGS.

Specifications

Our leaf chains are made of high-quality alloy steel and produced using precision technology to punch and squeeze the plates and machine the pin, bush, and roller. We also use high-efficiency automatic equipment and automatic grinding equipment to ensure precision and consistency. Our chains undergo heat treatment of carburization, carbon and nitrogen protection mesh belt furnace, surface blasting process, and are assembled with precision by internal hole position and spin riveted by pressure to ensure the performance of the entire chain.

We offer a range of surface treatments, including self-color, dark blue, and black. Our chains are available in various sizes and can be customized to meet your needs, with the AL, BL, LL, FL, and LH series available. We ship our products from any sea port or airport in China and offer various packaging options, including chain, plastic bag, color box, wooden case, or OEM.

Why Choose Us?

Our leaf chains are highly durable and made to the highest standards, including ISO, DIN, and ANSI. We have over 30 years of experience in making chains and chain links and have a design team with extensive experience in chain design. We offer the best service and prompt delivery and cover a production area of 18750 square meters. We have more than 100 employees and a complete set of testing equipment to ensure our quality.

Our company mainly supplies various products for industrial use, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We offer high-quality products, preferential prices, and considerate services, and customers are welcome to customize drawings and samples.

FAQs

1. What are leaf chains?

Leaf chains, also known as hoisting chains, are high-strength chains used in various industrial applications, including mining, construction, and agriculture.

2. What materials are used to make leaf chains?

Our leaf chains are made with high-quality carbon steel 40Mn and undergo heat treatment of carburization, carbon and nitrogen protection mesh belt furnace, surface blasting process, and are assembled with precision by internal hole position and spin riveted by pressure to ensure the performance of the entire chain.

3. What standards are followed in making leaf chains?

Our leaf chains are made to the highest standards, including ISO, DIN, and ANSI.

4. Can leaf chains be customized?

Yes, we offer customized leaf chains to meet your specific needs.

5. What other industrial products does your company supply?

Our company mainly supplies various products for industrial use, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

All the content of this page is from the Internet, and it is only provided as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are suitable for after-sales replacement and can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier.

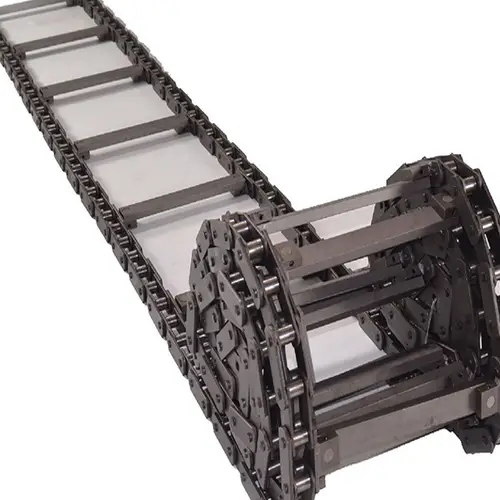

Performance Characteristics of Paver Chain

Paver chains exhibit several performance characteristics that make them highly suitable for various applications. These characteristics include:

– High tensile strength: Paver chains are designed to endure heavy loads and resist breakage, making them reliable and durable.

– Excellent resistance to wear and corrosion: Paver chains are made from materials that provide exceptional protection against wear and corrosion, ensuring long-lasting performance in harsh environments.

– Precise heat treatment: The heat treatment process used in manufacturing paver chains enhances their hardness and strength, resulting in improved performance and extended lifespan.

– Accurate pitch control: Paver chains are engineered to maintain precise pitch control, which allows for smooth and efficient operation in paver machines.

– Low maintenance requirements: Paver chains are designed to minimize the need for frequent maintenance, reducing downtime and increasing productivity.

Types and Characteristics of Paver Chain

Paver chains are available in various types, each with its own unique characteristics. Some of the common types of paver chains include:

– Roller chains: These chains consist of interconnected rollers that engage with the sprockets, providing smooth and reliable power transmission.

– Conveyor chains: Conveyor chains are specifically designed for conveying purposes, ensuring efficient material handling in paver machines.

– Engineering class chains: These heavy-duty chains are built to withstand extreme conditions and heavy loads, making them ideal for demanding applications.

Each type of paver chain offers specific benefits and is chosen based on the requirements of the application. For example, roller chains provide excellent flexibility and high-speed capability, while conveyor chains offer efficient material transportation.

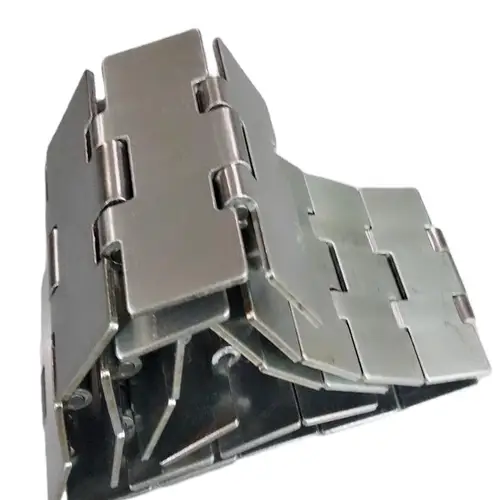

Advantages of Paver Chain made of Different Materials

Paver chains can be made from various materials, each offering distinct advantages. Some commonly used materials for paver chains include:

– Stainless steel: Paver chains made from stainless steel offer excellent resistance to corrosion and high temperatures, making them suitable for applications in harsh environments.

– Alloy steel: Paver chains made from alloy steel exhibit exceptional strength and durability, making them ideal for heavy-duty applications.

– Carbon steel: Paver chains made from carbon steel provide a cost-effective solution with good tensile strength and wear resistance.

The choice of material for a paver chain depends on the specific application requirements, considering factors such as operating conditions, load capacity, and budget constraints.

Application of Paver Chain

Paver chains find extensive applications in various fields, highlighting their value and importance. Some areas where paver chains are commonly used include:

– Asphalt Pavers: Paver chains play a crucial role in the smooth and efficient paving of asphalt roads, ensuring precise and accurate movement of the paver machine.

– Concrete Pavers: Paver chains are essential components in concrete paver machines, enabling precise control and alignment during the concrete paving process.

– Road Construction and Maintenance: Paver chains are vital for constructing and maintaining roads, ensuring the proper distribution and compaction of materials.

– Industrial Flooring: Paver chains are utilized in the construction of industrial flooring, providing stability and strength to withstand heavy equipment and traffic.

– Sports Facilities: Paver chains are instrumental in the creation of sports surfaces, such as tennis courts and running tracks, ensuring the uniform and precise application of materials.

The application of paver chains in these fields underscores their significance in achieving optimal results and maintaining the integrity of various structures.

Future Development Trends and Opportunities

The paver chain industry is poised for promising growth in the coming years, with several future development trends and opportunities to consider. Some of the key trends and opportunities in the paver chain market include:

– Increasing demand for sustainable and eco-friendly paver chain materials, driven by environmental regulations and the growing focus on reducing carbon footprint.

– Advancements in manufacturing processes, such as precision engineering and automation, leading to improved quality and efficiency in paver chain production.

– Growing infrastructure development activities worldwide, creating a significant demand for paver chains in road construction, urban development, and industrial projects.

– Technological innovations, such as the integration of sensors and smart monitoring systems in paver chains, enhancing performance and enabling predictive maintenance.

These trends and opportunities present a positive outlook for the paver chain industry, with immense potential for growth and innovation.

Choosing a Suitable Paver Chain

Selecting the appropriate paver chain is crucial for optimal performance and longevity. Several aspects should be considered when choosing a suitable paver chain:

1. Determine Application Requirements: Assess the specific requirements of the application, such as load capacity, operating conditions, and speed, to determine the appropriate type and characteristics of the paver chain.

2. Identify the Type of Chain: Based on the application, select the most suitable type of paver chain, whether it is a roller chain, conveyor chain, or engineering class chain.

3. Select the Chain Material: Consider the operating environment, including factors like corrosion resistance, temperature extremes, and durability, to choose the ideal material for the paver chain.

4. Consider the Chain Dimensions: Ensure that the dimensions of the paver chain, such as pitch, roller diameter, and overall length, align with the requirements of the machine and application.

5. Check Compatibility with Sprockets: Verify the compatibility of the selected paver chain with the corresponding sprockets, ensuring smooth engagement and optimal power transmission.

By following these considerations, you can select a suitable paver chain that meets the specific needs of your application, maximizing performance and efficiency.

Summary

In conclusion, paver chains possess distinct performance characteristics that make them highly suitable for various applications. Their types and materials offer specific advantages, ensuring reliable and efficient operation in different environments. The application of paver chains in various fields reflects their value and importance in achieving optimal results. The future development trends and opportunities in the paver chain industry present exciting prospects for growth and innovation. When choosing a suitable paver chain, careful consideration of application requirements, chain type, material, dimensions, and compatibility with sprockets is crucial. By selecting the right paver chain, you can ensure optimal performance and longevity in your application.

Author: Dream