China Professional Transmission Conveyor Chain P75 Outer Curved Plate Chain Industrial Chain Paver Chain with Centre Slot Lowes Air Compressor

Product Description

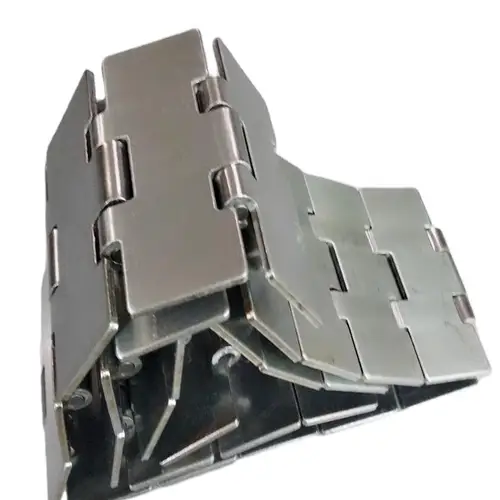

The China Professional Transmission Conveyor Chain P75 Outer Curved Plate Chain is a high-quality industrial chain made of stainless steel. It is designed for heavy-duty applications in various industries. The chain has undergone a heat treatment process, resulting in high temperature hardening for increased durability. The surface of the chain is treated with polishing, providing a smooth and polished finish. It is available in different colors such as elf, dark yellow, dark blue, and black.

Product Introduction

The P75 Outer Curved Plate Chain is widely used in building material shops, manufacturing plants, and machinery industries. It is a standard chain that offers a large reduction ratio, allowing for efficient power transmission. The chain can be used with long shaft center distances, enabling flexibility in installation. It can also be used on both sides to drive multiple shafts simultaneously. The installation and replacement process is simple, as the chain is easy to cut and connect. Additionally, if the distance between shafts is short, the chain can be used vertically.

The P75 Outer Curved Plate Chain offers several advantages over other power transmission methods. Its sprocket diameter can be smaller than a belt pulley while transmitting the same torque. The chain’s design also results in less wear of sprocket teeth compared to gears. Furthermore, the chain drive provides greater shock absorption, making it suitable for applications that require durability and reliability.

Chain Plate

The chain plate of the P75 Outer Curved Plate Chain is made of heat-treated carbon/alloy steels, ensuring high tensile strength. The plate undergoes a shot peening process to improve fatigue resistance, enhancing the overall performance of the chain.

Roller

Hardened carbon/alloy steels are used for the rollers of the P75 Outer Curved Plate Chain. This material provides excellent wear resistance and rigidity. Similar to the chain plate, the roller also goes through a shot peening process to enhance fatigue resistance.

Bush

The P75 Outer Curved Plate Chain utilizes case hardened alloy steels for the bushings. These bushings have external and internal hardened surfaces, ensuring high wear resistance. They are accurately set into the link plates, contributing to the overall strength and durability of the chain.

Pin

The pins of the P75 Outer Curved Plate Chain are made of alloy steels known for their high wear resistance and toughness. Surface hardening can be applied upon request, further enhancing the performance and longevity of the chain.

Other Products

Our company, specializing in industrial products, offers a wide range of high-quality products for various applications. Some of our products include:

- Agricultural Gearboxes

- Power Output Shafts

- Sprockets

- Fluid Couplings

- Worm Gear Reducers

- Gears and Racks

- Detachable Chains

- Pulleys and Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings

We take pride in offering high-quality products at competitive prices. Our products are known for their durability, reliability, and excellent performance. We also provide customization options, allowing customers to request specific drawings and samples. Our company is dedicated to delivering exceptional products and services to meet the diverse needs of our customers.

Frequently Asked Questions (FAQs)

- Q: What certifications does your factory have?

- Q: Can your products be produced according to samples?

- Q: Do you test all products before shipping?

- Q: What is your delivery time?

- Q: What is your sample policy?

A: Our factory has obtained IAF ISO and TS16949 certifications, ensuring the highest quality standards.

A: Yes, we have the capability to produce products based on your samples or technical drawings. We can even build molds and fixtures to meet your specific requirements.

A: Yes, we conduct 100% quality testing before delivering our products. We take full responsibility for ensuring product quality and customer satisfaction.

A: If we have stock, we can ship the products immediately within a week. If not, the delivery time usually ranges from 7 days to 35 days, depending on the quantity ordered.

A: We provide samples for approval. For 1 or 2 samples, there will be no charge, but the customer is responsible for the courier fee. The courier fee can be refunded when an order is placed.

All the content of this page is from the Internet, and it is only provided as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are suitable for after-sales replacement and can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier.

Performance Characteristics of Paver Chain

Paver chains exhibit several performance characteristics that make them highly suitable for various applications. These characteristics include:

– High tensile strength: Paver chains are designed to endure heavy loads and resist breakage, making them reliable and durable.

– Excellent resistance to wear and corrosion: Paver chains are made from materials that provide exceptional protection against wear and corrosion, ensuring long-lasting performance in harsh environments.

– Precise heat treatment: The heat treatment process used in manufacturing paver chains enhances their hardness and strength, resulting in improved performance and extended lifespan.

– Accurate pitch control: Paver chains are engineered to maintain precise pitch control, which allows for smooth and efficient operation in paver machines.

– Low maintenance requirements: Paver chains are designed to minimize the need for frequent maintenance, reducing downtime and increasing productivity.

Types and Characteristics of Paver Chain

Paver chains are available in various types, each with its own unique characteristics. Some of the common types of paver chains include:

– Roller chains: These chains consist of interconnected rollers that engage with the sprockets, providing smooth and reliable power transmission.

– Conveyor chains: Conveyor chains are specifically designed for conveying purposes, ensuring efficient material handling in paver machines.

– Engineering class chains: These heavy-duty chains are built to withstand extreme conditions and heavy loads, making them ideal for demanding applications.

Each type of paver chain offers specific benefits and is chosen based on the requirements of the application. For example, roller chains provide excellent flexibility and high-speed capability, while conveyor chains offer efficient material transportation.

Advantages of Paver Chain made of Different Materials

Paver chains can be made from various materials, each offering distinct advantages. Some commonly used materials for paver chains include:

– Stainless steel: Paver chains made from stainless steel offer excellent resistance to corrosion and high temperatures, making them suitable for applications in harsh environments.

– Alloy steel: Paver chains made from alloy steel exhibit exceptional strength and durability, making them ideal for heavy-duty applications.

– Carbon steel: Paver chains made from carbon steel provide a cost-effective solution with good tensile strength and wear resistance.

The choice of material for a paver chain depends on the specific application requirements, considering factors such as operating conditions, load capacity, and budget constraints.

Application of Paver Chain

Paver chains find extensive applications in various fields, highlighting their value and importance. Some areas where paver chains are commonly used include:

– Asphalt Pavers: Paver chains play a crucial role in the smooth and efficient paving of asphalt roads, ensuring precise and accurate movement of the paver machine.

– Concrete Pavers: Paver chains are essential components in concrete paver machines, enabling precise control and alignment during the concrete paving process.

– Road Construction and Maintenance: Paver chains are vital for constructing and maintaining roads, ensuring the proper distribution and compaction of materials.

– Industrial Flooring: Paver chains are utilized in the construction of industrial flooring, providing stability and strength to withstand heavy equipment and traffic.

– Sports Facilities: Paver chains are instrumental in the creation of sports surfaces, such as tennis courts and running tracks, ensuring the uniform and precise application of materials.

The application of paver chains in these fields underscores their significance in achieving optimal results and maintaining the integrity of various structures.

Future Development Trends and Opportunities

The paver chain industry is poised for promising growth in the coming years, with several future development trends and opportunities to consider. Some of the key trends and opportunities in the paver chain market include:

– Increasing demand for sustainable and eco-friendly paver chain materials, driven by environmental regulations and the growing focus on reducing carbon footprint.

– Advancements in manufacturing processes, such as precision engineering and automation, leading to improved quality and efficiency in paver chain production.

– Growing infrastructure development activities worldwide, creating a significant demand for paver chains in road construction, urban development, and industrial projects.

– Technological innovations, such as the integration of sensors and smart monitoring systems in paver chains, enhancing performance and enabling predictive maintenance.

These trends and opportunities present a positive outlook for the paver chain industry, with immense potential for growth and innovation.

Choosing a Suitable Paver Chain

Selecting the appropriate paver chain is crucial for optimal performance and longevity. Several aspects should be considered when choosing a suitable paver chain:

1. Determine Application Requirements: Assess the specific requirements of the application, such as load capacity, operating conditions, and speed, to determine the appropriate type and characteristics of the paver chain.

2. Identify the Type of Chain: Based on the application, select the most suitable type of paver chain, whether it is a roller chain, conveyor chain, or engineering class chain.

3. Select the Chain Material: Consider the operating environment, including factors like corrosion resistance, temperature extremes, and durability, to choose the ideal material for the paver chain.

4. Consider the Chain Dimensions: Ensure that the dimensions of the paver chain, such as pitch, roller diameter, and overall length, align with the requirements of the machine and application.

5. Check Compatibility with Sprockets: Verify the compatibility of the selected paver chain with the corresponding sprockets, ensuring smooth engagement and optimal power transmission.

By following these considerations, you can select a suitable paver chain that meets the specific needs of your application, maximizing performance and efficiency.

Summary

In conclusion, paver chains possess distinct performance characteristics that make them highly suitable for various applications. Their types and materials offer specific advantages, ensuring reliable and efficient operation in different environments. The application of paver chains in various fields reflects their value and importance in achieving optimal results. The future development trends and opportunities in the paver chain industry present exciting prospects for growth and innovation. When choosing a suitable paver chain, careful consideration of application requirements, chain type, material, dimensions, and compatibility with sprockets is crucial. By selecting the right paver chain, you can ensure optimal performance and longevity in your application.

Author: Dream